ProTool Rotary Brush 39 inch (100cm) Water Powered

Quick Overview

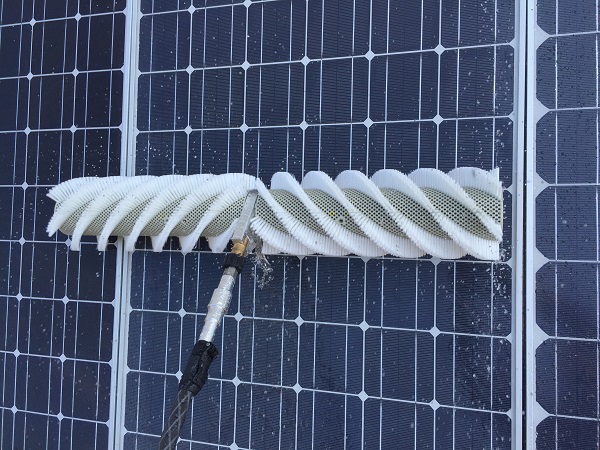

- Designed to clean solar panels, vinyl, and aluminum siding

- It is a mobile, hand-operated unit designed to be controlled manually

- Hydrokinetic brushes save considerable time compared to traditional brushes

- Requirements: 580 psi at brush head max and 2.3 gallons per minute consumption

Show More

$3,010.30

$3,431.50

Brush 39in Water Powered for Cleaning Large Surfaces

For Pressure washing sizing the brush is the same usage as a #7 tip

Pressure washer:

Weight: 12.5lbs

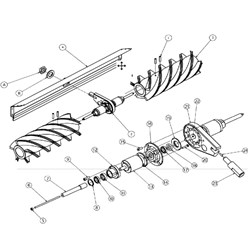

Rotating Brush User Manual

Instructions for Use:

- Connect the brush to the telescopic lance.

- Position the unit on the surface to be cleaned.

- Open the water valve on the telescopic lance.

- Begin cleaning the surface.

Stopping the Brush - Turning off the cleaning

- Close the telescopic lance’s valve.

- Turn off the water supply

- Open the telescopic lance’s valve to discharge the residual pressure.

We recommend the Gardiner SLX Pole for supporting and using this rotary brush. The first section is removed to insert the brush support and hose

Either:

the SLX 27 (less 5ft for 22ft of reach)

155-4275or the SLX 39ft (Less 5ft offers 34ft or reach) 155-4391

Specifications:

Width: 39 in. (1000mm)Diameter: 5.9 in. (150mm)

Weight: 10 lbs (4.5Kg)

Bristle: 0.6 in.(15mm)

Attachment: M22 x 14MM Connector

CLEANING COATED OR PAINTED SURFACES

Using water on glued parts may cause them to become detached. Do not use the unit on wood floors or parquet that are not well-sealed.

Be careful when cleaning doors, parquet, painted surfaces or surfaces coated with synthetic products, and aluminum panels.

Before using the brush, we advise performing a test on a portion of the surface that is not in view, to prevent damage or alterations during cleaning.

PRODUCTS TREATED – HANDLED OR GENERATED

The Solar Panels treated with the brush should be comprised of modules with a maximum tilt of 35°.

Verify in the photovoltaic system’s operating manual the type of brushes that can be used for cleaning it, so as not to cause abrasions on the panels’ film.

It is important to avoid all operating situations that could cause repeated and unexpected stops of the brush’s rotation, such as those specified below:

- In the case of surfaces comprised of panels, the maximum distance between them must be 3 cm to prevent the unit from dropping into the empty space between one panel and the next.

- The surfaces must be as free as possible of protruding bodies such as long screws, brackets, and terminals, which could obstruct brush rotation or rip out its bristles.

- The unit is not designed to withstand heavy accidental impacts, such as those caused by being dropped, or those that are less intense but repetitive, such as those resulting from operating in stepped areas.

- It is also very important that the operating pressure not exceed the maximum value indicated in the “Technical Specifications” in order to prevent excessively high rotation speeds from causing premature wear of the unit’s mechanical parts.

- When not in operation, never allow the unit’s weight to rest on the rollers’ bristles so as not to bend them.

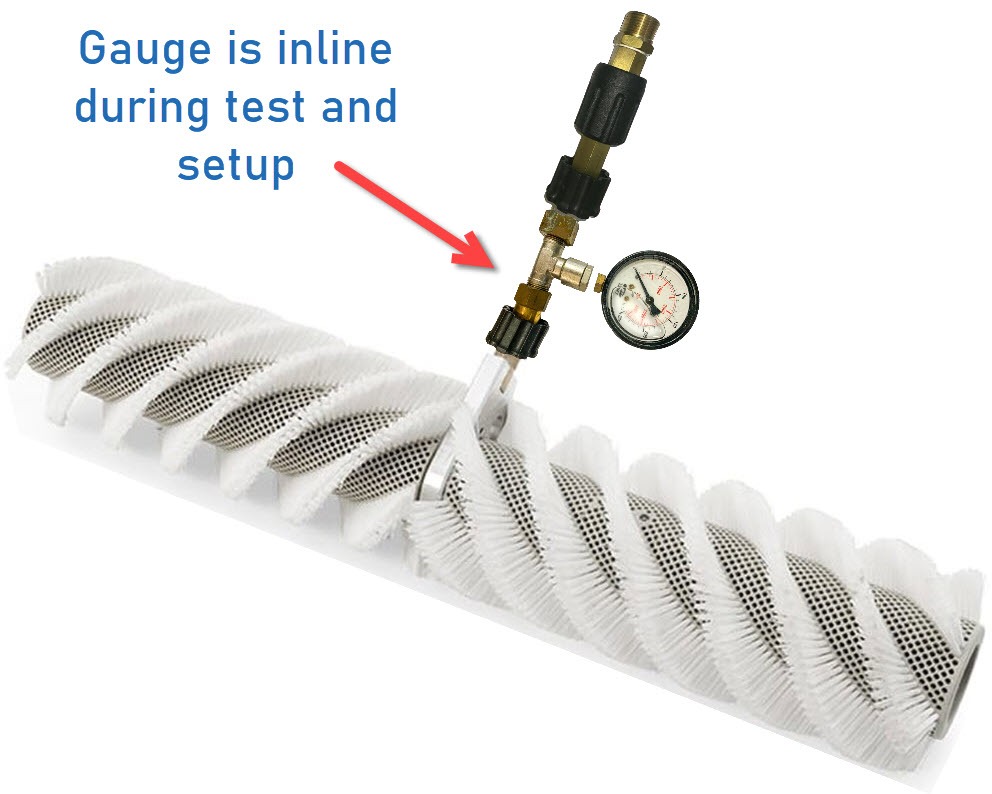

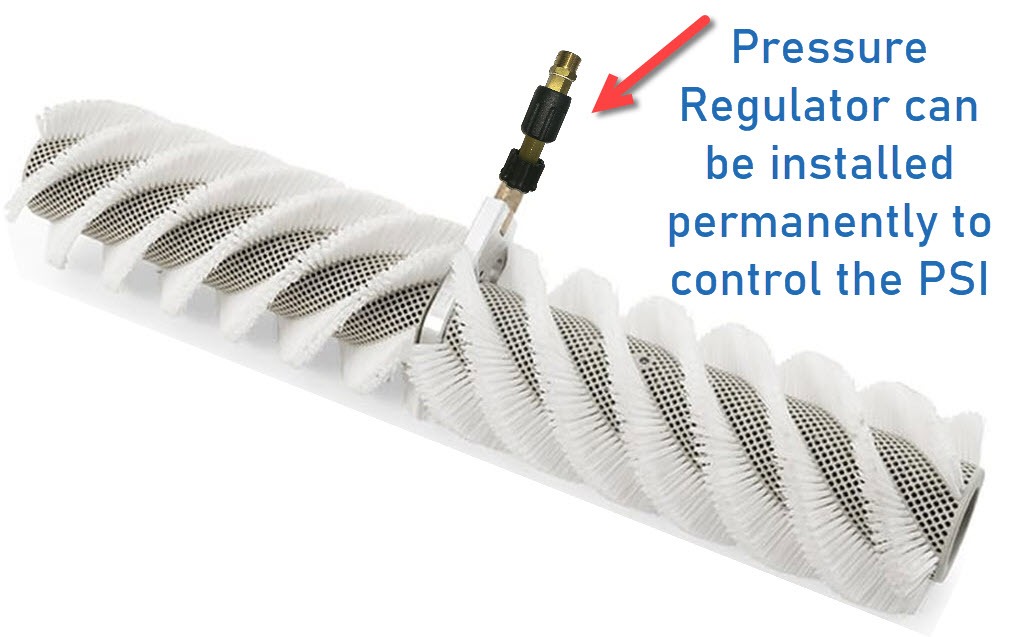

Regulator and Gauge

Use a Pressure Gauge to undestand the pressure at the brush

Install the Gauge on the water connector on the brush

Test Run your your pressure washer and supply water to the brush from your running pressure washer the PSI should be between 290 psi and 725 psi.

One you have your system setup at the correct pressure ytou can remove and store the gauge for future testing

Alway test again after a pressure washer has been worked on or should a different pressre washer is put in place to power the brush

NOTE:

If your pressure Washer is running the brush at more that 725PSI then immediatly stop the water flow.

You can try a smaller pressure washer or install and adjust a Pressure Regulator to set the pressure to the suggested 600 to 650 psi to run the brush. (Max 725psi)

How to check your Flow from your Pressure Washer

- 1min 50 seconds (2.7 gpm) and

- 2 min 20 seconds (2.14 gpm)

Regulator and Guage not included

Testing and Setting Water Pressure

If your pressure washer is to big you will need to usea Pressure Regulator to control the Pressure - Target 600 to 650 PSI.

Here the gauge is installed

Attached to the Pressure washer and run the brush, ig you are between 550 and 650psi you are good to go.

Attach a Pressure Regulator and Test, Set PSI

If the pressure is more than 725 PSI then install and adjust a pressure regulator to the target of 600 to 650psi. (Max 725)

Gauge can be removed for day to day use

Once you know your settings are correct you may remove th egauge for day to day cleaning

Keep the gauge handy should the pressure washer used be swapped out so you can test again

Proposition 65 requires businesses to provide warnings to Californians about significant exposures to chemicals that cause cancer, birth defects or other reproductive harm. These chemicals can be in the products that Californians purchase, in their homes or workplaces, or that are released into the environment. By requiring that this information be provided, Proposition 65 enables Californians to make informed decisions about their exposures to these chemicals. Proposition 65 also prohibits California businesses from knowingly discharging significant amounts of listed chemicals into sources of drinking water. Proposition 65 requires California to publish a list of chemicals known to cause cancer, birth defects or other reproductive harm. This list, which must be updated at least once a year, has grown to include approximately 900 chemicals since it was first published in 1987. Proposition 65 became law in November 1986, when California voters approved it by a 63-37 percent margin. The official name of Proposition 65 is the Safe Drinking Water and Toxic Enforcement Act of 1986.

The list of chemicals contains a wide range of naturally occurring and synthetic chemicals that include additives or ingredients in pesticides, common household products, food, drugs, dyes, or solvents. Listed chemicals may also be used in manufacturing and construction, or they may be byproducts of chemical processes, such as motor vehicle exhaust. For more information visit www.p65warnings.ca.gov/