Spare parts for ProTool RODI Production and Delivery IBC System - Parts list

ProTool RODI Production and Delivery IBC System - Parts list

4 User Delivery System on IBC Tank with 3 High Flow RO membranes

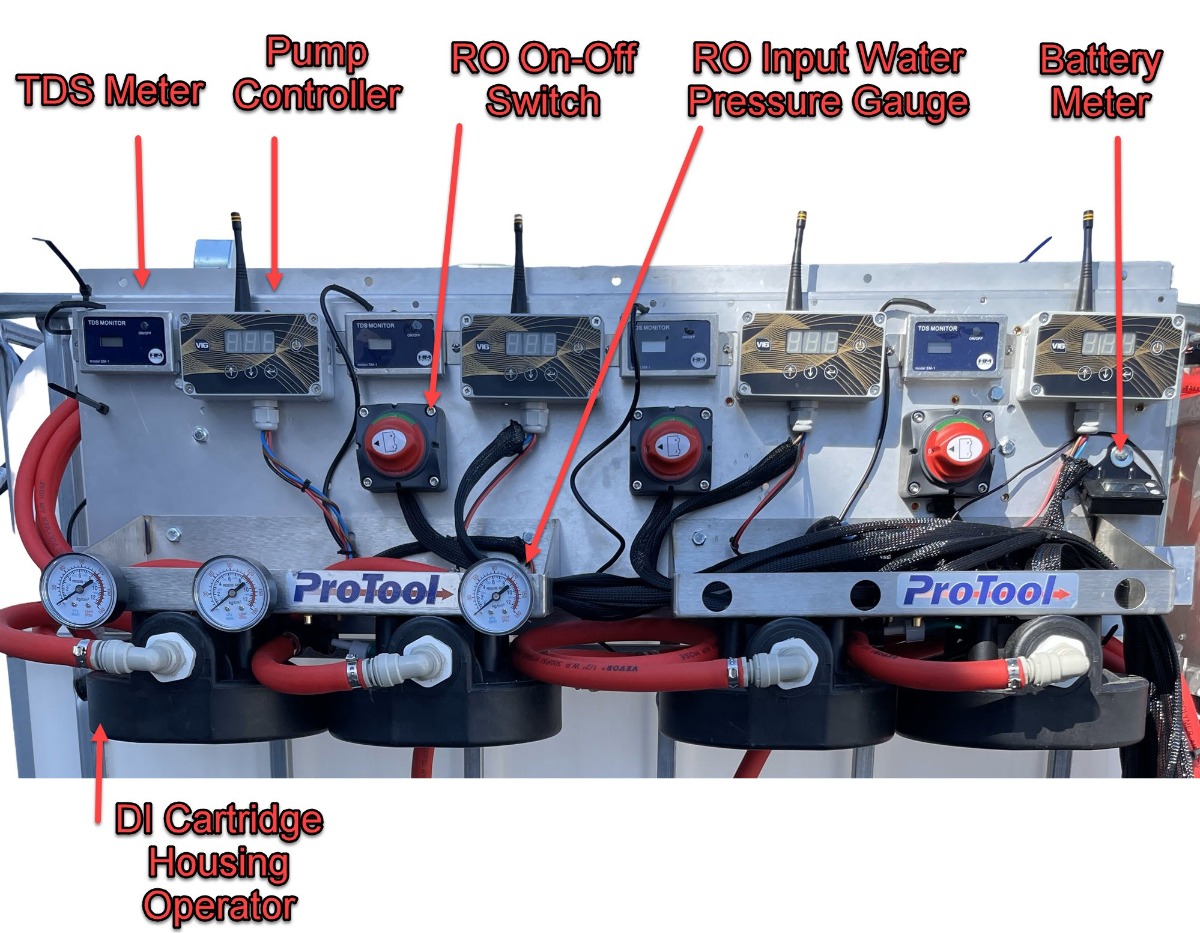

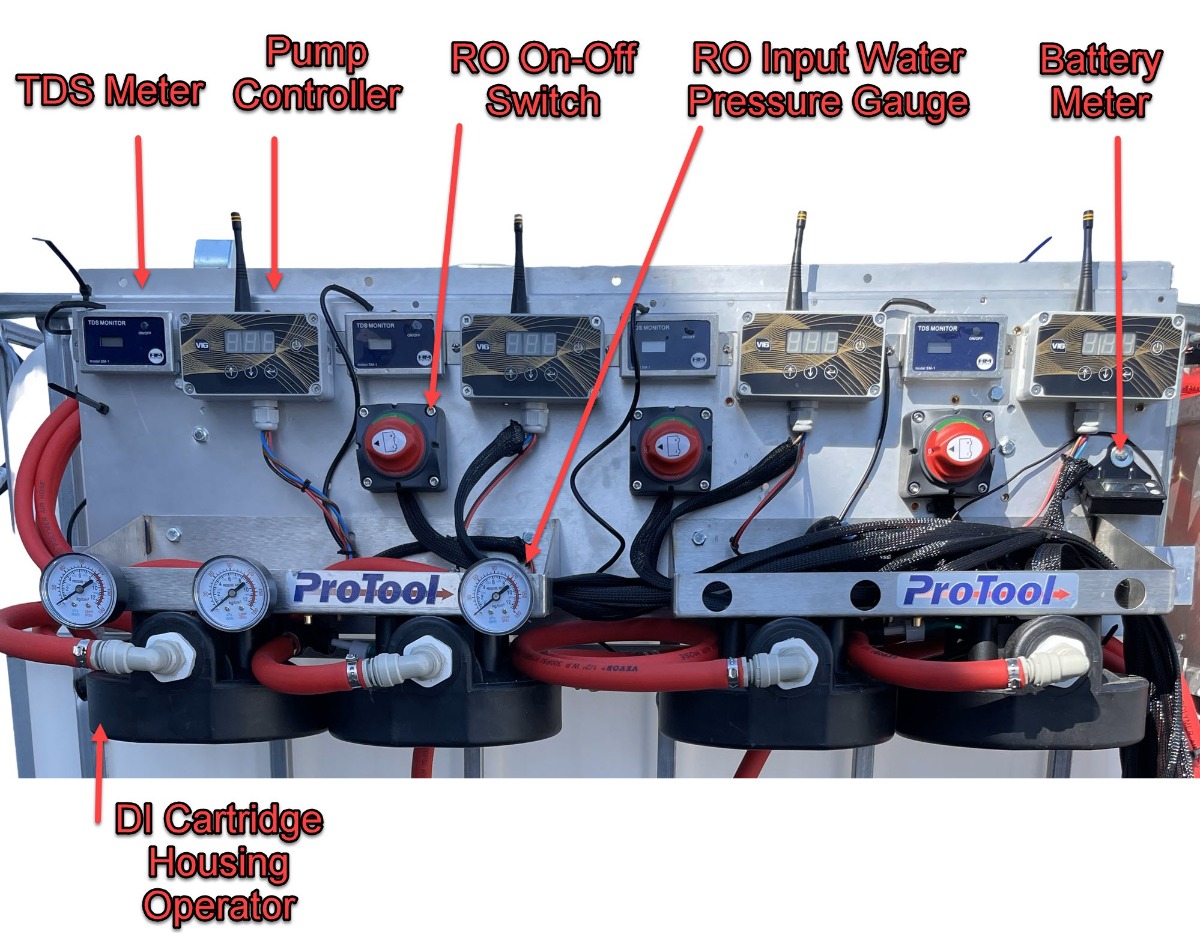

This system supports RO Water Permeate production of 4.5+ gallons per minute into the IBC Tank, and 4 independent operator delivery systems drawing from the tank each with their own pump, pump controller, TDS Meter and DI Resin Cartridge for the final polish of the RO water to Zero TDS

Detailed Description

RO Water Creation into the 270 Gallon IBC Tank

This system brings in Tap Water at Tap Water pressure

Designed to operate at best efficiency when

- the Inlet water has a pressure is 50+ PSI

- the water flows at least 6 Gallons per Minute (> 6 GPM)

This will produce RO Water Production into the tank will be greater than 4.5GPM and stay well ahead of the 4 operators consumtion

Note: Should the pressure and/or the water flow not be at these levels then water production will be less

The RO Pumps are controlled by a switch and and a level sensor installed in the tank.

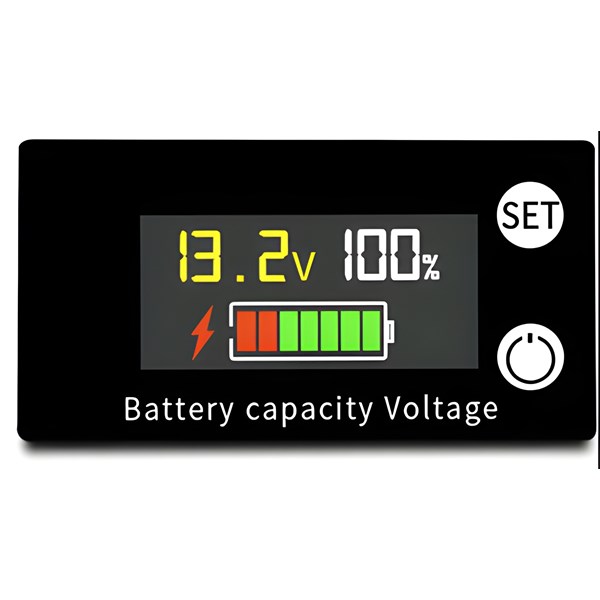

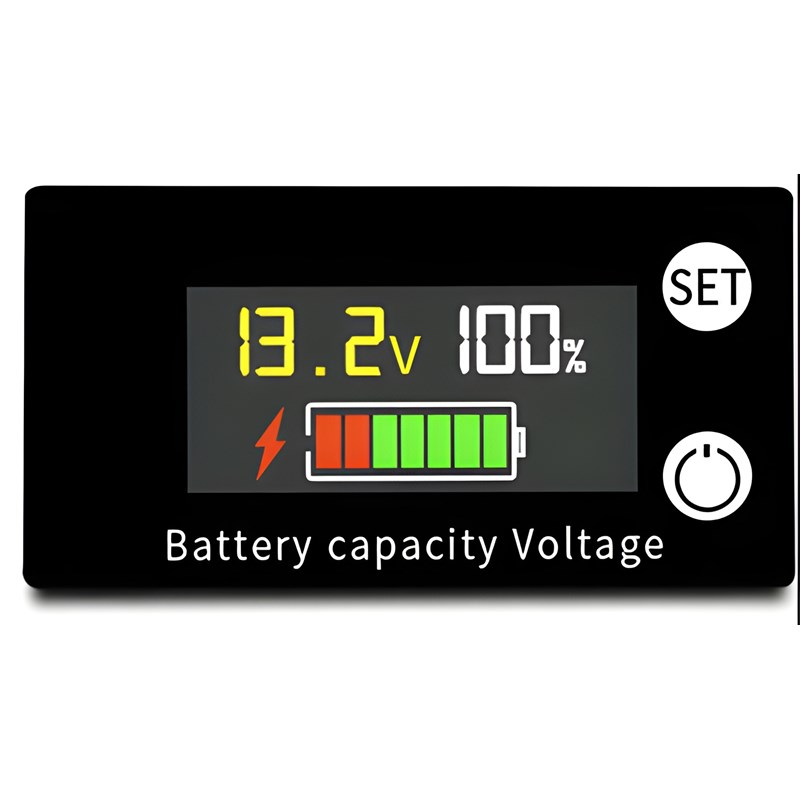

The three ROs will draw a total of 48 amps of 12v power (600 watts) from a battery bank of 4 qty 100amp hour batteries will last all day (Batteries not included)

Alternatively the RO Pumps could be operated from 3 qty 12v 300 watt waterproof power bricks drawing the 600 wats from 110v drawing about 6 amps of power

RO Permeate (RO production water) is created and stored in the IBC tank up to 270 gallons

RO Flush Water is combined and sent to a flush hose for routing to landscaping (EPA Rules do allow us not route curbside or into the gutter)

There is a flush valve per RO Membrane that is used to Flush the Membrane of excess contaminants ate the beginning and end of RO Permeate water production

RO Permeate production into the IBC Tank can be performed independent of the Operator consumption

Operator Pure Water Delivery

4 Identical Operator DI pure water filtration and Delivery Pump Systems with Remote Control Pump Controllers

The RO Water produced above is drawn from the IBC Tank by a 1 gpm delivery pump - 1 per operator-

The Operator has control over the flow they need for their water fed pole both from the pump controller on the operator panel and the remopte control fob offering on - off flow up and flow down on the fob.

Each operator has their own dedicated DI Resin Cartridge and TDS meter to monitor the pure water status from the cartridge

The Pure water output is routed to an operator hose, typically a reel with 200 to 300ft of delivery hose. (reel and hose not included)

The pumps draw about 5 amps of 12v current, 5 running together is 20 amps of power or 240 watts and will connect to a battery bank of 2 qty 100 amp hour batteries that be used to run all 4 the pumps for a working day.

Alternatively a single 300watt 110v to 12v power supply could be used this would draw 3 amps of 110

Together the RO Pumps and Delivery Pumps would draw about 1000 watts or about 9 amps this is accommodated on most household and commercial 110v sockets we would recommend a generator sized at 1800 watts if you wanted to run the system from a small quiet generator

If you choose to run from the battery packs mentioned above:

- The RO Battery Pack will need a 40amp battery charger to restore the battery pack overnight (10 hours)

- The Delivery Pump Battery pack would need a 20amp Battery charger to recharge in 10 hours

-wAVgV4.jpg)

Follow this link to the Product Parts list page for this system

https://www.jracenstein.com/p/protool-electric-plate-mount-ibc/890-09911

Note:

Oetiker clamps and a tool and cutter set are included for maintenance and repair and allow you to plumb and connect the reels to the Operator Panel

There is also several sets of spare parts to handle the maintenance little things that may get broken from time to time

This is the first Video and covers how to mount the Plates to the IBC

How we recommend that you go about attaching the plates to your IBC

Overview of Operator Plate panel

Overview of tds connections on Operator Panel to run the hose to the 4 Reels

Overview of Delivery Pumps and Operator Plate panel, connect reel hose from tds probe to Reels

Some of the items will need to be installed once you have all of the panels attached to the IBC

This is the first Video and covers how to mount the Plates to the IBC

RO Membrane Plate to Delivery Pump

RORO Bypass hoses from RO to place the RO Flush Valves

RORO Bypass hoses from RO to place the RO Flush Valves

RORO Bypass hoses from RO to place the RO Flush Valves

RO Pumping Plate explanation and wire paths

RO Pumping Plate low am sensor tank full wire

e

RO Plate Water Inlet, RO Pumped lines 1, 2, 3 Battery Wire connection

e

What needs to be installed on the top of your tank

e

Reference for Testing the RO Membranes with a hand held tank

e

Tutorial on how to remove an Oetiker Clamp from the hose

e